Shoe Pattern

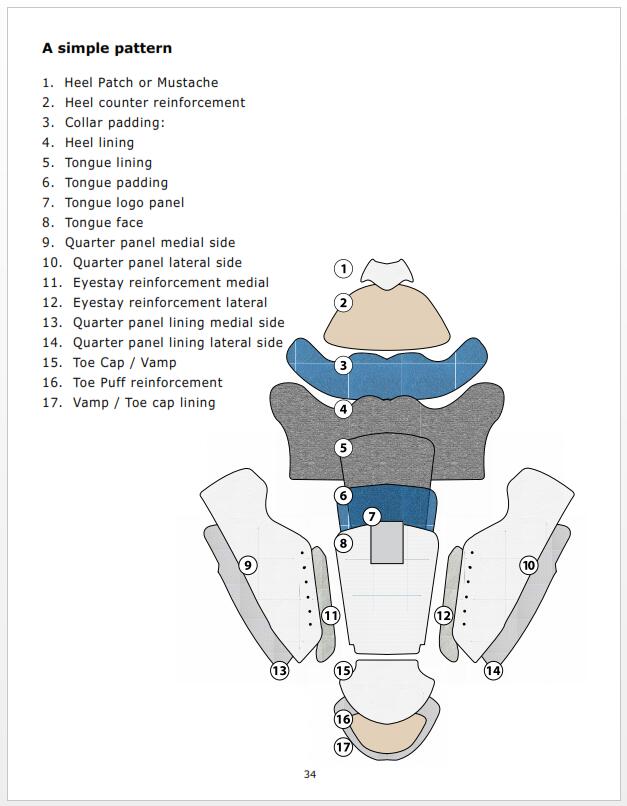

Shoe pattern will be finish before the sample make. Once the shoe design is completed, the factory Pattern Maker or Pattern Master takes over. The Pattern Master transfers the designer’s side proile, heel, and vamp drawings to “Shell” patterns of the shoe.

The shell is the blank, lat pattern matched to the surface of the last. Once the shoe design is transferred onto the shell, the Pattern Master has the actual shape of each pattern part.

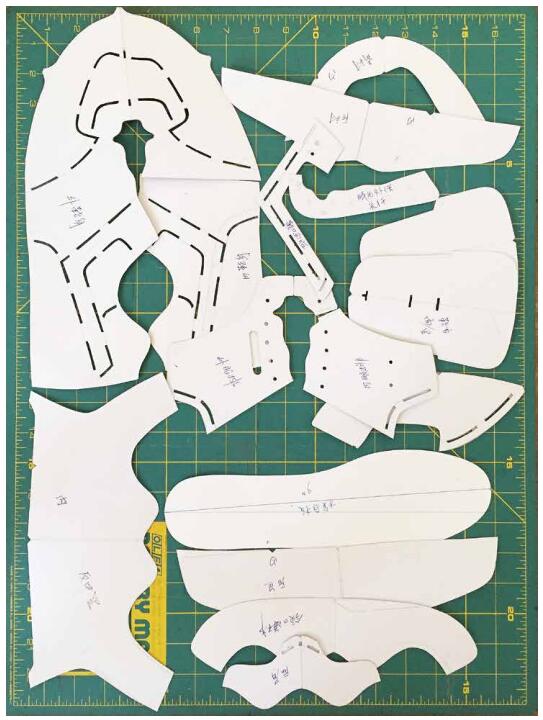

The Pattern Masters’ skill is what makes a shoe come to life. Pattern Masters work hard to follow the designer’s drawings, but they will also make adjustments so that the parts it together. Once the pattern is drawn it is hand cut from card stock.

The Pattern Makers Challenge

The pattern masters irst job is to get the last that has been selected by the designer and examine its shape. If it is a familiar last it’s a simple task to mark the throat opening and the shoe collar height. He may already have the “Shell Pattern” on ile. The shell pattern is what a one piece seamless upper would look like.

If the last is new the pattern maker may “tape” the last so he can create the shell pattern. He will cover over half the last with layers of tape, then carefully cut the tape along the center line of the last and along the bottom edge. At this stage he can draw the shoe design on the tape. Once the tape is peeled from the last and lattened you have the pattern!

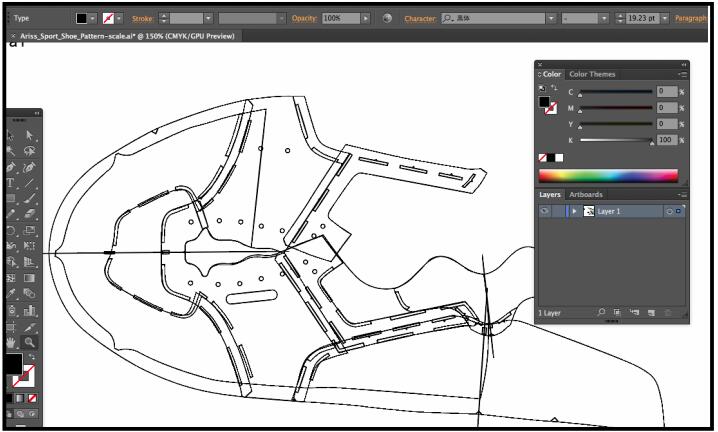

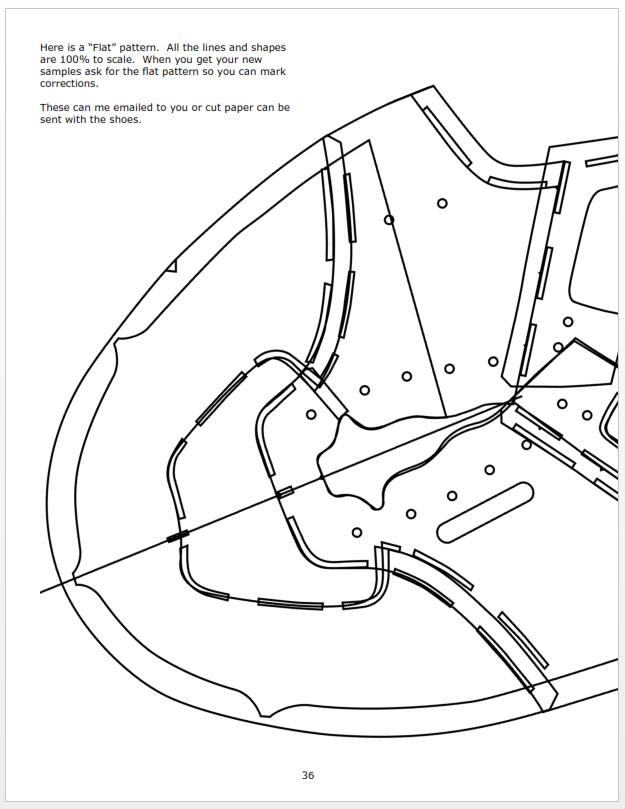

Now the pattern can be redrawn in a computer and cut out of heavy paper. As a designer you should always ask for the lat pattern of a new design. When you make corrections it’s easy to draw on the sample shoe then mark the shell pattern for the pattern maker.

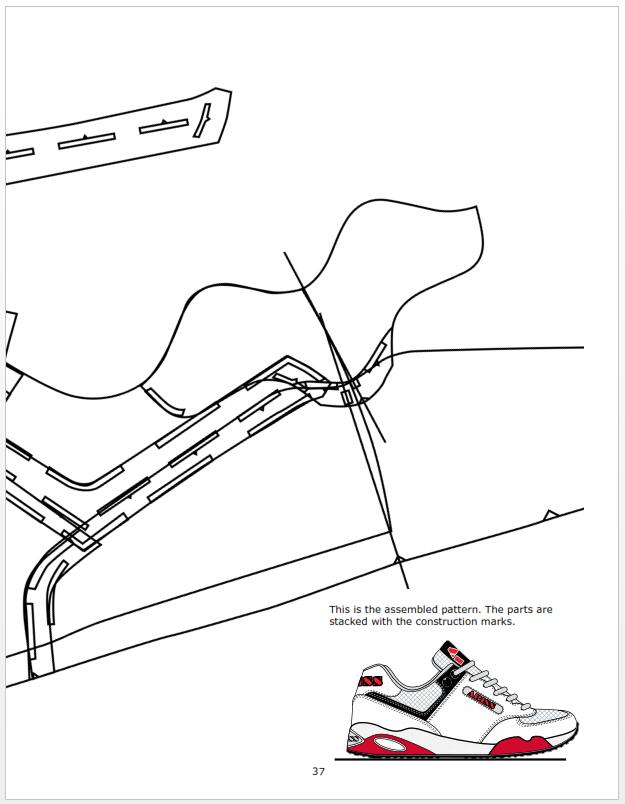

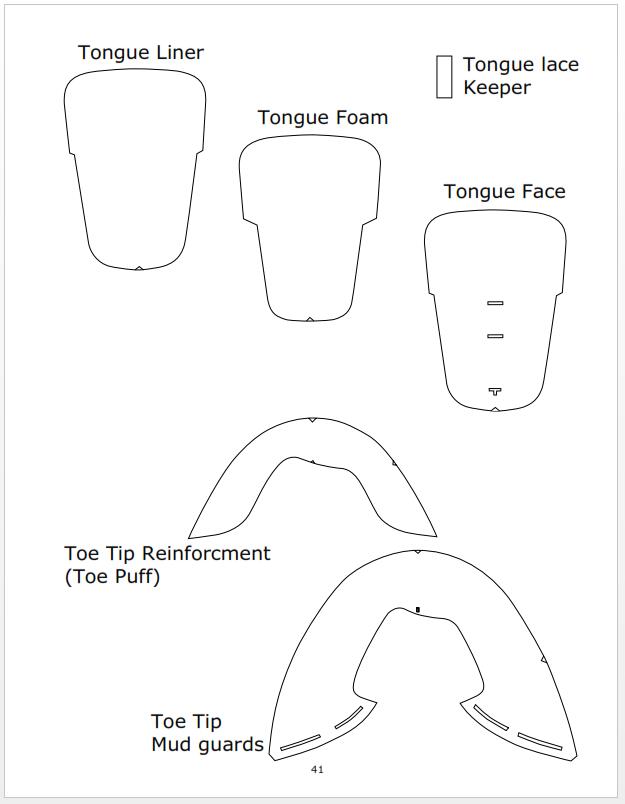

It is much faster to scan the corrections and email back to the factory, rather than Fed-Ex the shoe back to China. Here is the shoe designers drawing with the pattern makers actual pattern. For this lat pattern each shoe part can then be created.

What is the difference between a Shoe Designer and Shoe Pattern Maker?

A shoe designer is responsible for all aspects of the shoe’s design. The designer must consider the styling, materials, colors, customers, price, trends and product performance. The footwear pattern maker, while critical to the entire operation is really only responsible for creating a beautifully proportioned pattern that its tight to the last.

To be a great footwear designer, do you need to make your own patterns? In my experience, the answer is “no.” A shoe designer does not need to know how to make footwear patterns. It’s important that a shoe designer can read, work with, and adjust the patterns but the creation of the new pattern is best left to the “Pattern Master”.

How to make a shoe pattern

Making a shoe pattern is not hard! If you have time and patience you can make your own shoe pattern come to life with a few common tools. The techniques are simple, the process easy, but the skills to make a beautiful, well proportioned, mechanically sound shoe pattern takes years to perfect!

Here is a list of the tools you will need to make a shoe pattern:

1. A shoe last!

2. 1/2 inch masking tape.

3. A sharp X-Acto™ knife or hobby knife.

4. Pens and Pencil.

5. Small lexible steel ruler.

6. Stiff paper

Tape the shoe last

To make a new shoe pattern you will need to “tape” the last so you can pull the shell pattern. The tape should be layered in two different directions so the pattern stays together when you are ready to peel it off the last. You will start on the lateral or outside of the shoe last.

First lay the tape length wise down the lateral side of the last, starting at the top. Next run a stripe of tape down the center of the last from the top of the instep down to the toe. Do the same on the heel of the last. Finally, run layers across the last from the bottom edge up the side of the last. Make this extra smooth, this will be your drawing surface when you start marking your shoe pattern.

Make sure the tape wraps around the bottom edge of the last. You will need this edge, as it will become the bottom edge of your shoe pattern. If your shoe design is symmetrical then half the last is okay. If the medial and lateral side of your shoe design are different you will need to tape the entire last.

Mark the pattern on the last

Once the shoe last is covered with tape it is time to start marking the shoe pattern. With a steel ruler mark the center line of the last from the instep to the toe tip and down the heel. With the center lines marked it is time to start drawing the pattern on the last.

Drawing the shoe pattern

It’s fun to add a little color or to paste on a logo, you can start to get a feel for what the design will look like in 3D. Go ahead and make any changes to your design, this is your time to be creative. If you don’t like your line grab some tape to cover it up and try again.

Make a quick check of the top line, collar and heel notch heights. For a size 9 shoe (measuring from inside to the strobel sock) the collar line is 55mm, heel notch is 80-85mm to top eyelet hole 90mm. The design does not have to be perfect now but look out for any major laws. This is a good time to show it to your developer. Are the pattern parts wasting material? Are there any overlapping issues? Too many layers overlapping in the lex zone will cause problems.

Flatten the shoe pattern

After you have your shoe design down on the tape it is time to peel off the tape. Using a sharp blade cut the tape down the center lines toe and heel. Next cut the tape along the bottom edge of the last. Now start peeling off the tape. If the tape was laid down correctly in overlapping layers the pattern will pull off.

Here is the top pattern free of the last. You will ind that it does not lay lat, don’t worry.

Now carefully lay the tape on a sheet of stiff paper board and press your new shoe pattern lat. Starting at the top eyelet position and collar line work your way down the middle then out to each end. As you move to the heel and toe the 3D pattern will need some relief cuts to “Spring” the pattern. Add a few cuts and the pattern will latten.

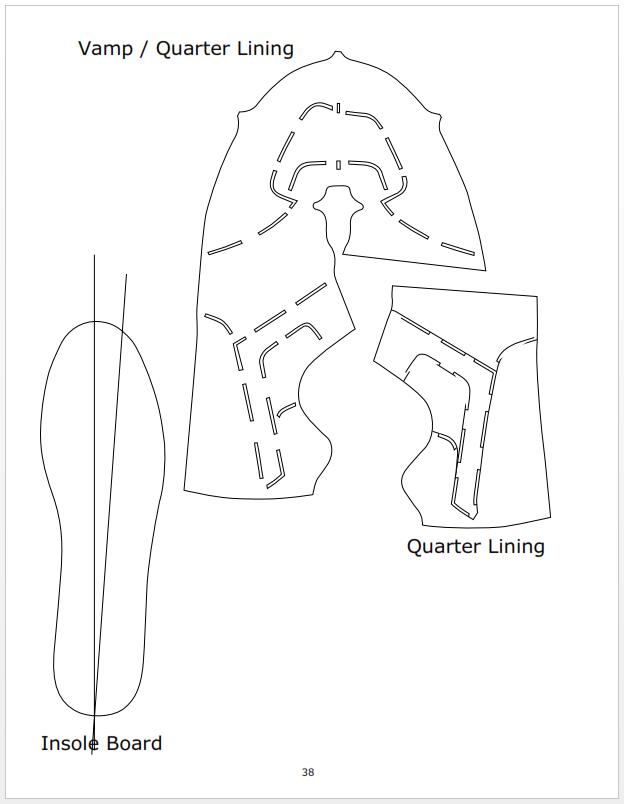

Once the tape is peeled from the last and lattened you have the shoe pattern! With the pattern attached to paper it’s time to trim out the pattern. The pattern with all the parts together is called the “shell” pattern. Now the shoe pattern can be redrawn in a computer, cut out of heavy paper.

As a shoe designer you should always ask for the lat pattern of a new shoe design. When you make corrections it’s easy to draw on the sample shoe then mark the shoe pattern for the pattern maker. It is much faster to scan the corrections and email back to the factory, rather than Fed-Ex the shoe back to China.

Know more about the process of shoe making.